What Is Inventory? Practical Guide for Smarter Inventory Management

Have you ever thought why there are some supershops you walk into with complete confidence? You know that whatever you need will be there. No tension or last-minute scrambling. You trust them because they manage it really well.

And then, there are those other stores. The ones where the shelves feel like time capsules stuck in the past. Whatever you search, you just find the same outdated products you’ve seen year after year. Inventory that’s not just outdated, it’s holding the business back.

So what sets these two kinds of stores apart? What builds success for one and pulls the other into stagnation? What creates a business that’s complete and thriving, versus one that’s stuck and struggling?

The answer is surprisingly simple: inventory.

Yes, it all begins there. And you’ll be amazed at how something as humble as inventory, when managed wisely, can shape the entire destiny of a business.

TL;DR

Inventory Isn’t Just Stuff. It’s the Secret Weapon for Success.

Inventory means the goods or materials a business stocks for selling or using in production. It includes raw materials, work-in-progress items, and finished goods. But it’s not just about the stock. It’s a critical factor that cash flow, customer satisfaction, and profitability of a business depend on.

Good inventory management means having the right items, in the right place, at the right time. That’s how you can avoid overstock, stockouts, and waste. There are some methods, including Just-in-Time (JIT), ABC analysis, EOQ, and safety stock strategies.

Top businesses use data, automation, and clearly defined systems to reduce errors and drive growth. Simple steps, such as cycle counting and utilizing inventory software, can significantly boost efficiency and profits.

Start by auditing what you have, identifying your best products, calculating turnover rates, and applying one consistent strategy. Because your path to sales, scale, and customer trust starts on the shelf.

We speak from knowledge, not just opinion. After talking to hundreds of business managers, we now know what is inventory and how it impacts a business.

So, let’s dive in. Let’s explore what inventory truly means, its types, importance, tips to follow, and mistakes to avoid. Let’s uncover how better inventory leads to better results and what you can do starting today.

What Is Inventory?

Inventory refers to the goods or materials a business holds with the intention of selling or using in production.

It’s everything you keep on hand to sell, build, or run your operations — whether that’s raw materials, work-in-progress items, or fully finished products waiting in a warehouse or on store shelves

In simpler terms: if a customer can eventually buy it, or if it goes into making something sellable, it’s part of your inventory.

Inventory isn’t just ‘stuff’. It’s money. Value. Opportunity. Whether it’s in boxes or bins or on a digital catalog, when you manage it well, your business runs smoothly: demand is met, waste is minimized, and those cringe-worthy “sorry, we’re out of stock” moments are avoided.

Manage it poorly, and you’re left with a lot of unsold products or empty racks during peak demand. From an accounting perspective, inventory is considered a current asset, something your business expects to sell or use within the year. And it’s a big deal financially.

Inventory affects your cash flow, profit margins, customer experience — basically, your entire business story. So whether you sell phones, furniture, or fresh-baked cookies, inventory is at the center of it all. Mastering it means mastering your business.

Understanding Inventory: Deep Dive with Facts and Stats

Let’s not sugarcoat it. Inventory can make or break a business. It often accounts for 25–30% of a company’s total assets, yet surprisingly, over 43% of small businesses still track it manually or don’t track it at all.

That lack of control? It’s costing U.S. businesses more than $1.1 trillion every year. On the flip side, companies that manage inventory well see up to 15% higher profitability than those that don’t.

Inventory Valuation: What You Choose Matters

If you want a successful business, you must choose how to value its inventory, and this choice impacts both taxes and profits.

- FIFO (First-In, First-Out): Older stock sells first, leading to lower costs of goods sold (COGS) during inflation, and up to 15% higher reported earnings.

- LIFO (Last-In, First-Out): Newer stock goes out first. It increases COGS and reduces taxable income, why 36% of US manufacturers use it for 2–5% annual tax savings (Note: LIFO isn’t allowed under international standards).

- Weighted Average: Spreads costs evenly. It’s simpler and used by about 28% of businesses.

Performance That Pays Off

Inventory isn’t just numbers, it’s performance. And the top players move faster and smarter:

- Top-performing companies hit 8–12 inventory turns/year. Average? Just 4–6.

- Each extra turn boosts return on assets by 2–3%.

- Automation cuts stockouts by 25% and slashes excess inventory by 35%.

- And with RFID tech, accuracy jumps to 99.5%, compared to 85–95% with manual methods.(Source)

Inventory management isn’t just a backroom process it directly affects your cash flow, customer satisfaction, and long-term growth. In fact, something as simple as choosing the right valuation method can shape your entire financial picture.

Types of Inventory

Businesses have to manage different types of inventory. It depends on the industry and their method of operation. That’s why understanding these types is essential. It keeps you organized, lets you meet demand, and helps you make faster decisions.

Manufacturing Inventory

If your business is manufacturing, you’re juggling three key categories.

- Raw Materials: These are the basic elements. The ingredients, parts, or supplies that haven’t been used yet. Just waiting to be turned into something valuable.

- Work-in-Progress (WIP): The inventory of the products that are partially built, assembled, or halfway through production, not quite ready, but on the way.

- Finished Goods: These are your done-and-dusted products. Fully completed, quality-checked, and all set to ship or hit the shelves.

Retail & Distribution Inventory

Retailers mostly deal with merchandise inventory. Finished products bought from suppliers. These go straight to your store (or website) and into the hands of customers.

It could be everyday stock, seasonal bestsellers, or limited-time offers. The game plan? Buy smart, sell fast, and restock just in time.

Service Inventory

Even service-based businesses have inventory. Just a bit less of it. For example, the managers have to keep count of hotel linens, salon tools, or cleaning supplies.

They’re not sold directly to customers, but they’re still crucial to the service they provide. If they need it to get the job done, they must track the inventory.

Specialized Inventory

And then, there’s the extra layer. The behind-the-scenes types that still make a big impact.

- Safety Stock: Your safety net. A backup buffer to avoid stockouts when demand spikes or suppliers slow down. Businesses keep around 10–20% of total inventory as safety stock.

- Seasonal Inventory: businesses need to keep a seasonal inventory containing products for offering during holidays, trends, or weather changes. Predictable, but still a challenge to manage well.

- Dead Stock: The stuff that just sits there. Outdated, expired, or no longer in demand. It eats up space and locks up cash. Identifying and offloading it is an underrated skill.

Inventory Management: Importance and Benefits

Inventory management is all about making sure the right products are in the right place, at the right time. Without drowning in extras or falling short.

Sounds simple, but don’t be fooled: bad inventory practices cost U.S. businesses over $1.1 trillion every year. Yes, trillion. The ones who get it right? They enjoy up to 15% higher profits. That’s not a small lift, that’s massive.

Benefits of Smart Inventory Management

Inventory done right isn’t just about tracking products. It’s about unlocking smoother operations, cash flow, more customers, and scalable growth. Here’s how smart inventory management gives your business the edge.

- Smooth Operations: No more guesswork. When your stock is under control, orders fly out on time, your team stays focused, and your systems actually work. Top performers turn inventory 8–12 times a year. Each extra turn boosts return on assets by 2–3%.

- Better Cash Flow: Too much stock? You’re tying up cash. Too little? You’re missing sales. Smart inventory management hits that sweet spot and frees up 20–30% more working capital. That’s money you can actually use.

- Happier Customers: Out-of-stock? Loyalty lost. When your shelves stay ready, your customers come back — simple as that. Solid inventory systems reduce stockouts by 25% and cut excess by 35%.

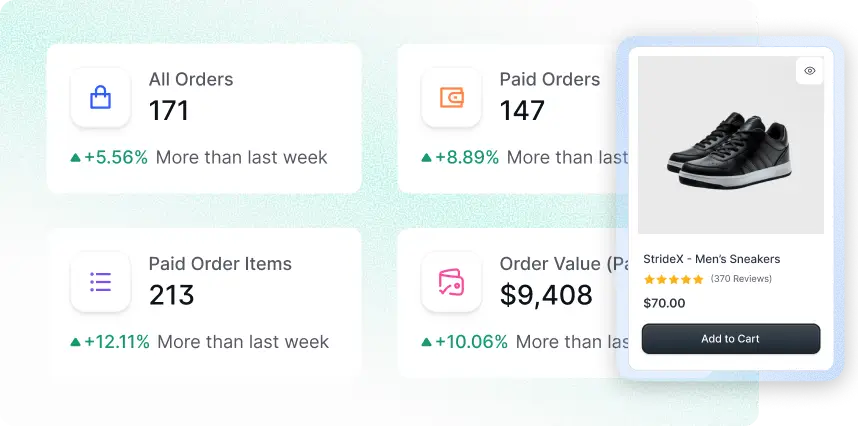

- Clearer Insights: Inventory isn’t just stuff — it tells you what’s working. You’ll know your top sellers, seasonal trends, margin drivers, and where you’re leaking money. Visibility leads to smarter moves.

- Ready to Scale: Growing fast with messy inventory? That’s chaos waiting to happen. Businesses that build smart systems early scale smoothly later, no scramble, no stress.

Inventory Management Methods

Inventory is the heart of every business, and getting your inventory management on point doesn’t mean you have to invest in massive systems or bulky teams. All you need are a few smart, useful, and timely methods that work.

We are listing inventory management techniques that keep businesses organized, profitable, and well-positioned for growth.

1. Just-in-Time (JIT)

The JIT method involves receiving inventory right when it’s needed. This minimizes the costs of holding and storing products.

Consider this method when demand is predictable, and your suppliers are reliable. Avoid it if your lead times are long and the supply chain is subject to unexpected disruptions.

2. ABC Analysis

Inventory items have different values, so it makes sense to segment them according to their impact on revenue:

- A: High value and low volume- Priority product

- B: Moderate value and volume- Important but not that much critical

- C: Low value and high volume- don’t consume too much attention, still matters

It makes sense to keep a closer eye on A-items because that’s where the majority of your profits come from.

3. Economic Order Quantity (EOQ)

With EOQ, you can determine the ideal order quantity to reduce the overall cost of ordering and holding.. The EOQ formula is best for those products that have steady and predictable demand.

4. Safety Stock

Safety stock is the stock you hold in anticipation of future demand peaks, supplier delays, or unforeseen events.

As a rule, it is good to start with 10–20% of your average inventory as a safety stock, but the percentage may vary depending on your business, tolerance to risk, and past fluctuations.

5. Materials Requirement Planning (MRP)

MRP is a forward-looking system that relies on sales forecasts to plan inventory needs. You evaluate upcoming demand, then make sure the raw materials and components are available to meet it.

It’s especially useful in manufacturing. If there’s a large order on the horizon, your system ensures that everything from base materials to small components is prepped for production. The key is accuracy. The better your forecasts, the smoother your operations.

6. Days Sales of Inventory (DSI)

DSI is a metric that tells you something powerful: how long (on average) it takes to sell the inventory you have. A lower DSI generally means you’re moving products quickly, which improves liquidity and reduces the risk of holding outdated stock.

But DSI varies by industry. You have to track the numbers and the changes over time. That’s how you spot trends and take action before any inventory issue.

Inventory Management Best Practices

The perfect inventory management method depends on various factors. It depends on your business type, the size, products, and seasons. Some businesses will rely heavily on one method. While others may combine several to create a system that fits their unique flow.

The point is: you don’t need to do it all. You just need to do what works consistently, clearly, and with a plan. Because when your inventory is in sync with your daily operations, growth doesn’t just happen. It becomes the norm.

Common Inventory Management Mistakes to Avoid

Inventory Management of your business can make or break your brand. If you do it correctly, it lowers your system losses, raises customer satisfaction, and maintains seamless operations.

But when it’s off?

Delays, waste, stockouts, and lost profits are the results. View the most typical inventory errors and learn how to prevent them.

1. No Inventory Visibility

The issue: If you don’t have a clear view of inventory, your stockouts, overstocking, and bottlenecks are at full risk.

The solution: Use an Inventory Management System (IMS) and track stock in real time and automate alerts.

2. Poor Space Utilization

The issue: Disorganized warehouses slow down operations and waste space.

The solution: Optimize layout using ABC analysis and vertical storage. Keep fast-moving items easily accessible.

3. Untrained Staff

The issue: Mistakes happen when employees aren’t trained in systems or processes.

The solution: Provide continuous training and system refreshers to ensure accuracy and efficiency.

4. Weak Communication

The issue: Poor collaboration between departments causes delays and errors. Weak communication makes strong misalignment

The solution: Set up shared tools and regular check-ins between inventory, sales, and purchasing teams.

5. No Seasonal Planning

The issue: In businesses, ignoring seasonal fluctuations leads to overstock or empty shelves. No seasonal forecasting is like an inventory bug.

The solution: Use business historical data and stats. Some product forecasting tools can help you plan and adjust inventory levels proactively.

6. Inaccurate Inventory Counts

The issue: Inaccurate data returns with wrong counts, low or overstock, and customer complaints.

The solution: Switch to cycle counting, small, regular checks instead of one big annual count.

7. Overstocking

The issue: Overstocks in the inventory tie up cash and risk obsolescence.

The solution: Adopt Just-in-Time (JIT) ordering where appropriate. And obviously, build the best connection and a reliable supplier network.

8. Skipping Technology

The issue: Manual processes are slow and error-prone.

The solution: Invest in modern inventory tools — even basic software can improve speed and accuracy.

9. Ignoring Inventory Data

The issue: Decisions made without data lead to repeated mistakes.

The solution: Use reporting tools in your IMS to analyze turnover rates, demand patterns, and order trends.

10. Purchasing Blind

The issue: Buying without knowing what’s in stock leads to over-ordering or missed items.

The solution: Use your IMS to forecast needs and set reorder points based on actual sales and stock levels.

Final Verse: Understand Inventory, Master Inventory Management

Let’s take a quick moment to recap.

- Inventory isn’t just boxes in storage. It’s the engine behind your cash flow, customer experience, and ability to grow. Yes, working capital matters, but so do the everyday metrics: reorder points, carrying costs, turnover rates, and accurate valuation.

- Stock counting is only one aspect of smart inventory management. It’s much more about placing deliberate orders, making clear forecasts, and maintaining organization from shelf to delivery. When done correctly, it lowers errors, stops losses, and maintains smooth operations.

We tried to cover it all. From foundational concepts to strategies. But information alone won’t move your business forward. Action will.

Start with this simple 4-week plan:

Week 1: Run a full inventory audit. What do you have, where is it, and what’s it worth?

Week 2: Use ABC analysis to identify your top-performing products.

Week 3: Calculate the key numbers. Find turnover rate, carrying costs, and reorder points.

Week 4: Follow one inventory management technique and implement it from scratch.

Start small. Be consistent. Build as you go.

Remember those two stores we talked about earlier? One earned customer trust through smart inventory practices. The other lost it through disorganization. The difference wasn’t luck. It was management.

So, is your inventory working for you, or holding you back?

Because business success doesn’t start with a sale.

It starts on the shelf.

Leave a Reply